A sophisticated, electrically driven, vibrating coring system that can extract optimum samples at speed in depths of up to 1000 m or more.

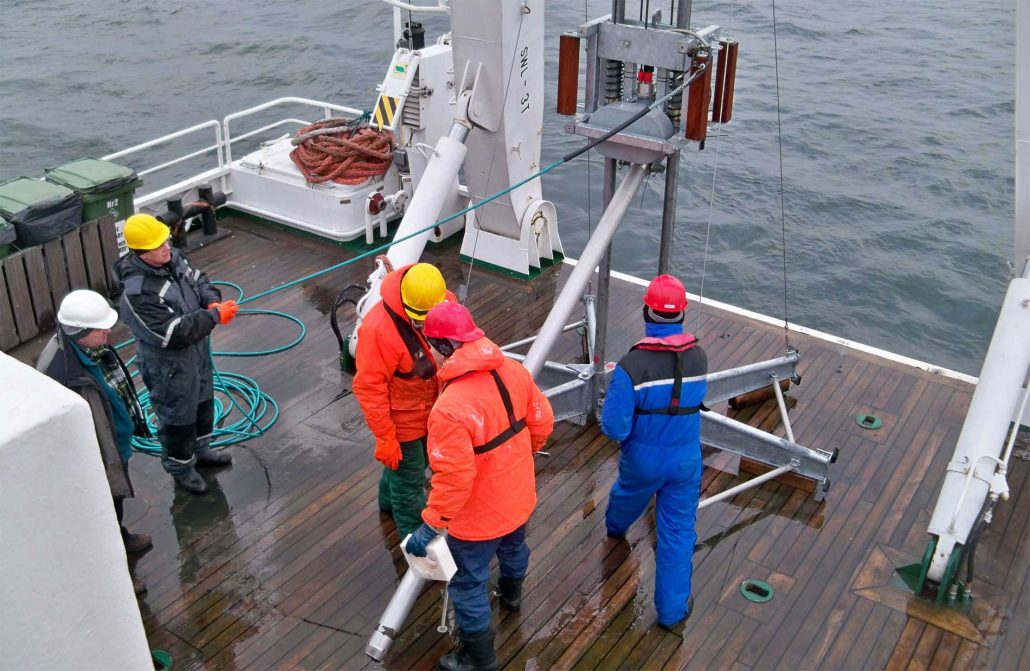

The original KUMO Vibrocorer – VC(VKG) 3/6/9 – has been successfully operating in harsh climates and challenging deep sea conditions for many years. Satisfied clients include Federal Maritime and Hydrographic Agency Germany, MMT Sweden, Fugro and Geo Marine Survey Systems (Geo-Corer) Netherlands, Next Geosolutions Italy and Jan De Nul Belgium.

The KUMO Vibrocorer is available for full purchase including all additional equipment and consumables required. If your operation only requires the Vibrocorer for a set period of time, we can provide the equipment on a rental or lease basis regardless of your project length.

Application:

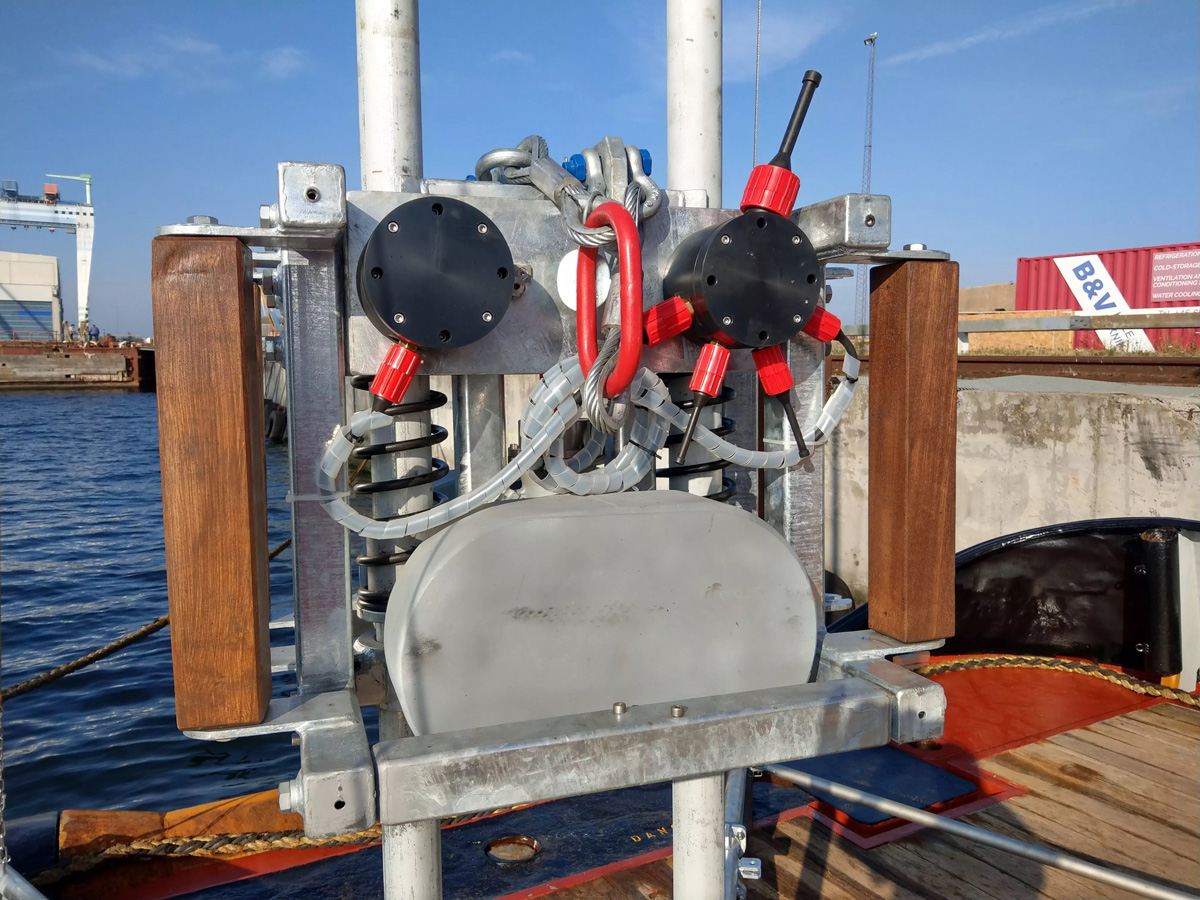

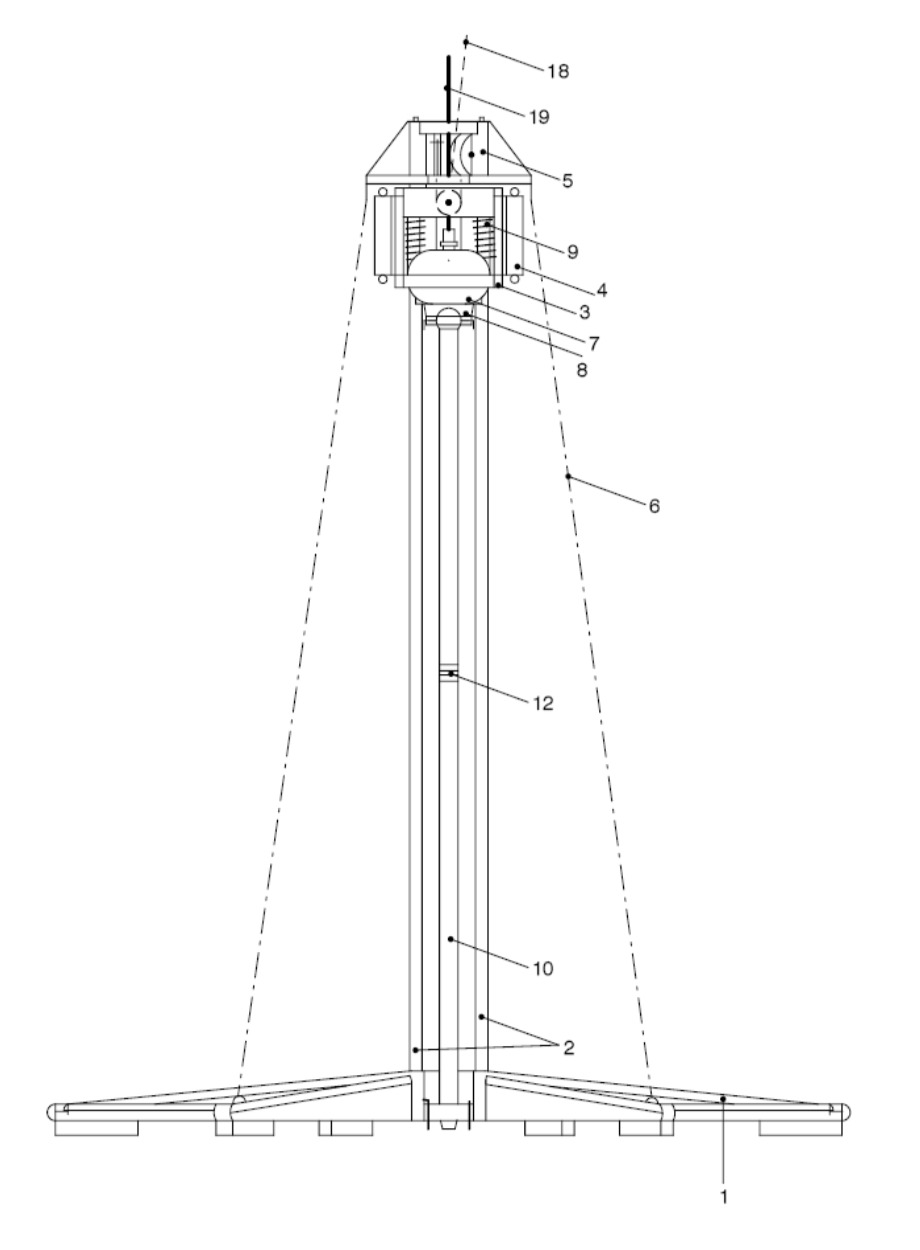

Smaller and lighter than others on the market, the advanced KUMO Vibrocorer is the only coring system in its class to have just 4 main components, making manual assembly fast and straightforward. The variable vibrating and penetrating forces operate independently, resulting in maximum penetration power and far greater efficiency at overcoming friction in sediments. The KUMO Vibrocorer can therefore successfully penetrate all sand and gravel types, as well as stiff stratums such as permafrost sediments and crusts of gas hydrates.

Runtime of the vibrator unit is unlimited, though typical penetration/extraction time is fast at just 5 minutes. The unique design of cutters, catchers and valves enables maximum filling of the barrel. There is no need to dismantle the core barrel while extracting the core sample, due to a patented flip-aside barrel design which greatly increases efficiency and reduces downtime. The simple, sophisticated design of the KUMO Vibrocorer increases core extraction quantity to around 40 cores/sites per day.

Features / Benefits:

- Up to 40 cores/sites extracted per day

- Just 5 minute penetration and extraction time (with unlimited runtime)

- Unique decoupling design resulting in minimum vibrational deadweight

- Maximum filling of the barrel with unique flip-aside design, no need to dismantle

- 4 main components for fast, easy handling and minimum downtime

- Geared penetration can be dramatically increased to penetrate well into stiff stratums

- Variable uploads allow 2 m per minute penetration speed

- Small size and weight in comparison to competitors

- Can be operated on smaller vessels with winch/lift capacity just 20 kN

The KUMO Vibrocorer can be adapted to meet specific project requirements, providing ultimate sample control and data transmission. For example:

- A standard core barrel length of 6 m can be adjusted all the way down to 3 m

- Split barrels are available up to 9 m, with transparent liners for enlarged dimensions

- Umbilical fibre-optics for deep sea exploration

- Battery-driven option with memory-based control and data storage

- Sonic, remote control option

| KUMO- VC(VKG)-3 |

KUMO- VC(VKG)-6 |

KUMO- VC(VKG)-9 |

|

|---|---|---|---|

|

Max. core length

|

3000 mm | 6000 mm | 9000 mm |

|

Core barrel diameter (inside)

|

102 / 96 mm (liner) | ||

|

Core barrel diameter (outside)

|

108 mm | ||

|

Max. working deepness

|

250 m / 1000 m | ||

|

Height

|

4.50 m | 7.50 m | 10.50 m |

|

Basement diameter

|

2.70 m | 4.60 m | 6.50 m |

|

Gross weight (excl. uploads)

|

0.75 to | 0.85 to | 0.95 to |

|

Gross weight (full uploads)

|

1.0 to | 1.1 to | 1.2 to |

|

Power supply (threephase AC)

|

380 – 440 V, 4 kVA, 50-60 Hz | ||

|

Vibrating force

|

30 kN / 7.5 kN (deep water) | ||

|

Vibrating frequency

|

28 Hz / 14 Hz (deep water) | ||

|

Corrosion protectio

|

hot zinced / stainless steel | ||

|

Transport

|

dismantled | ||

Contact us